Heat Exchanger Fabrication Specialists

Shell & Tube Heat Exchangers are used in applications where the demands from high temperatures and pressures are significant. Bendel manufactures heat exchangers for a variety of industries, for projects that include power plants, chemical plants, petrochemical plants, petroleum refineries, natural gas processing operations, and sewage treatment facilities.

A heat exchanger is a piece of equipment built for the purpose of efficiently transferring heat from one medium to another.The media may be separated by a solid wall, so that they never mix, or they may be in direct contact. At Bendel, we customize every heat exchanger project to the specific demands of each application, to suit our client's needs.Our in-house engineering team stresses definition of design, testing, fabricating, and quality control at each stage of development. We are advanced users of exceptional engineering and design software systems including HTRI, AutoCAD, and Compress.

Heat Exchanger Classifications

There are two primary classifications of heat exchangers according to their flow arrangement:

Parallel-Flow Heat Exchangers: In parallel-flow heat exchangers, the two fluids enter the exchanger at the same end, and travel in parallel to one another to the other side.

Counter Flow Heat Exchangers: In counter-flow heat exchangers the fluids enter the exchanger from opposite ends. The counter-current design is most efficient, in that it can transfer the most heat from the heat (transfer) medium.

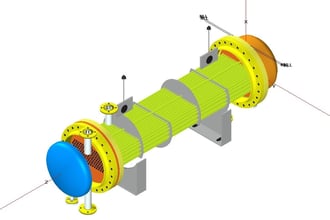

Shell and tube heat exchangers consist of a series of tubes. One set of these tubes contains the fluid that must be either heated or cooled. The second fluid runs over the tubes that are being heated or cooled so that it can either provide the heat or absorb the heat required.

The set of tubes is called the tube bundle and can be made up of several types of tubes: plain, longitudinally finned, and studded. Shell and tube heat exchangers are typically used for high-pressure applications (with pressures greater than 30 bar and temperatures greater than 260°C), as their shape and structure makes them particularly robust.

Superior Heat Exchanger Machining & Drilling

Our Quickmill Intimidator is the superior solution for large part machining and drilling accuracy. The Quickmill gives us increased production efficiency while improving the quality and performance of our Shell & Tubesheet Heat Exchangers.

Our Intimidator Gantry 96 (96″ x 185.5″) provides our craftsmen with a powerful, precise tool that performs flawlessly time after time.

Machining & Drilling Services

Bendel accepts drilling outsource project work, allowing clients to benefit from our superior tools - and the convenience of optionally shipping their own materials to us OR choosing for us to purchase materials on their behalf and ship finished products directly to their door.

Vertical Lathe

Learn more about our heat exchanger fabrication solutions here.

Or to find out more about our specific fabricated products, please contact us via the web here or call us at: (+1) 866.596.5112