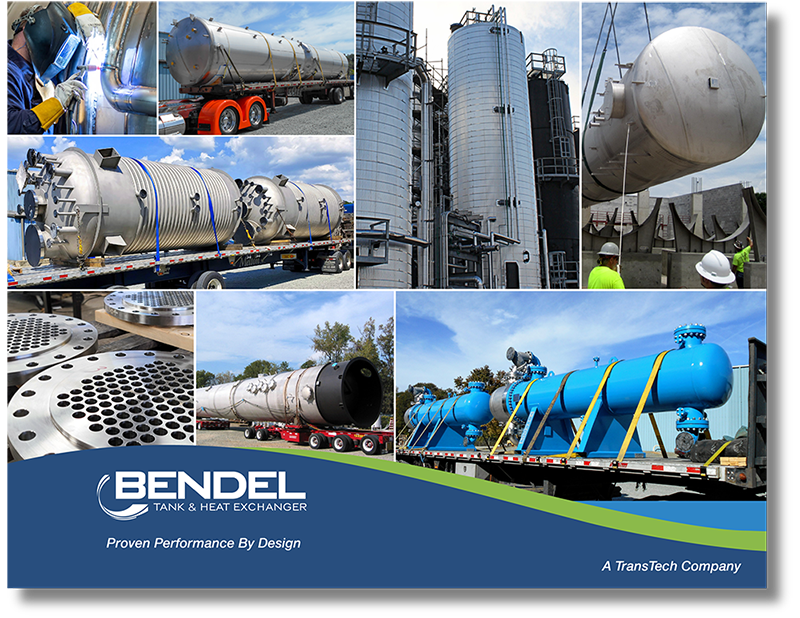

Petrochemical & RefiningEquipment Fabrication

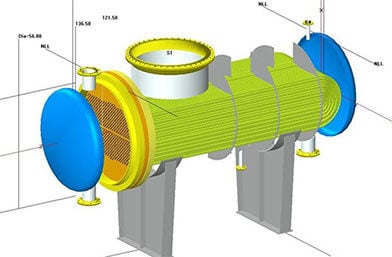

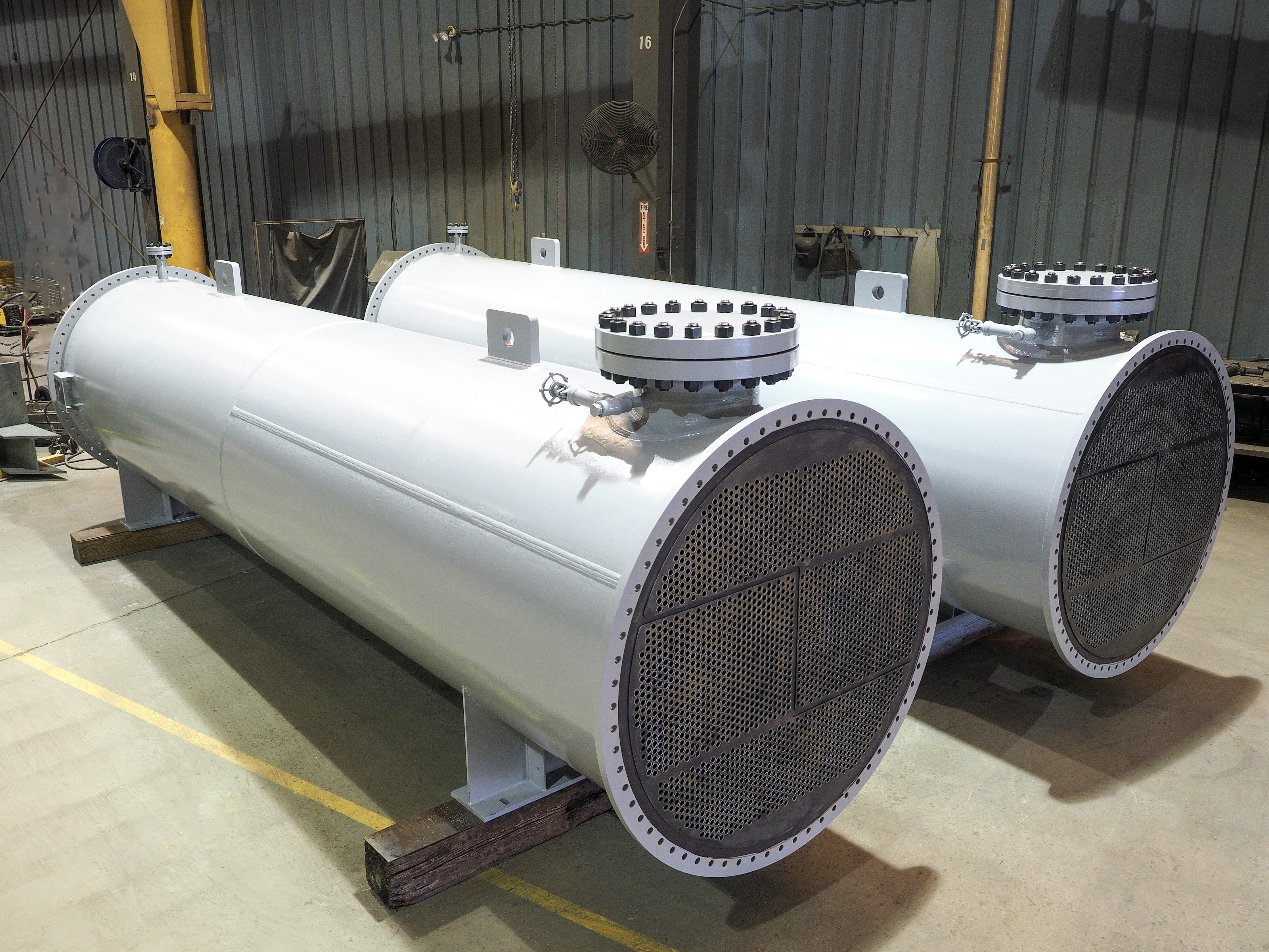

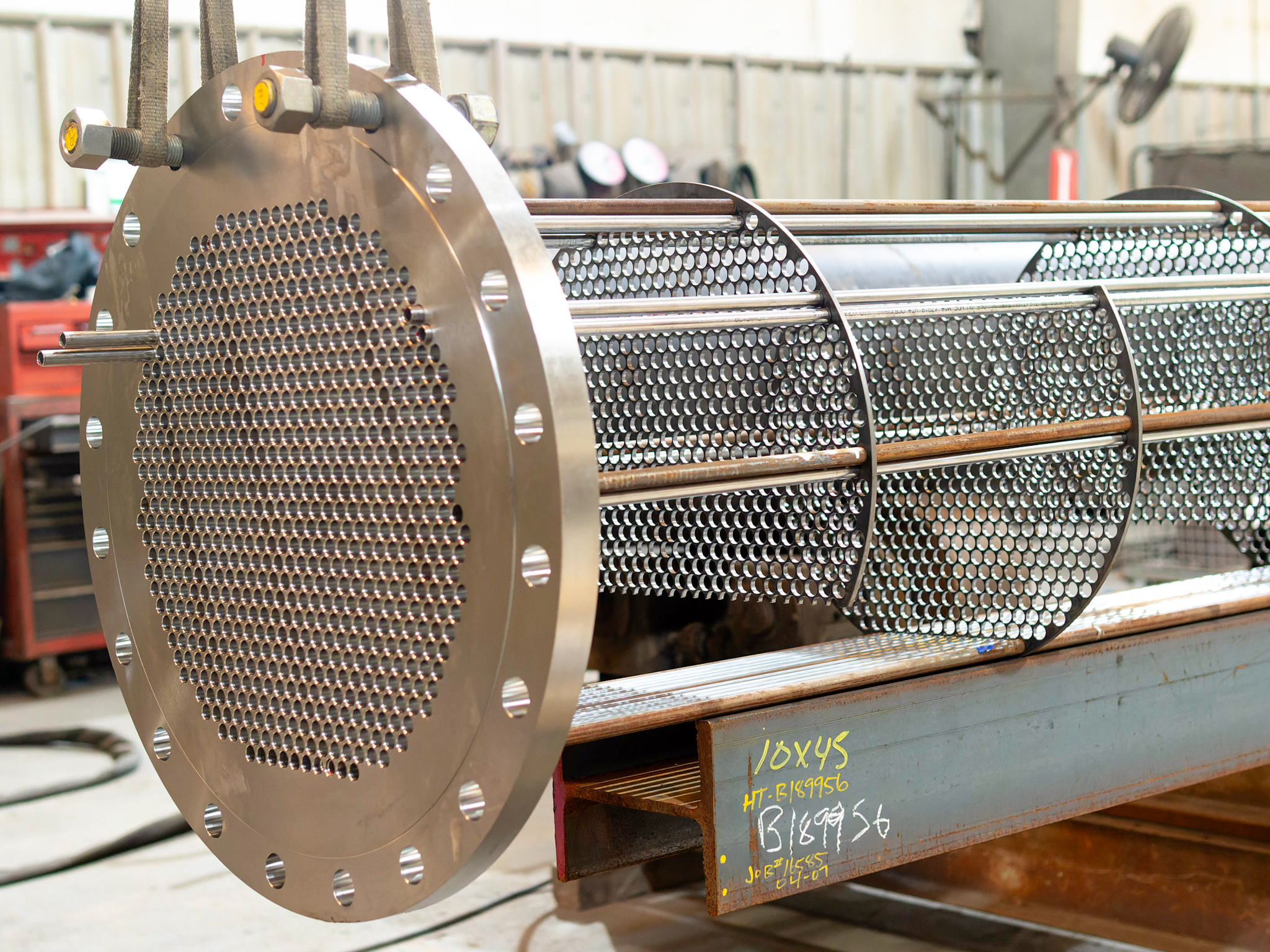

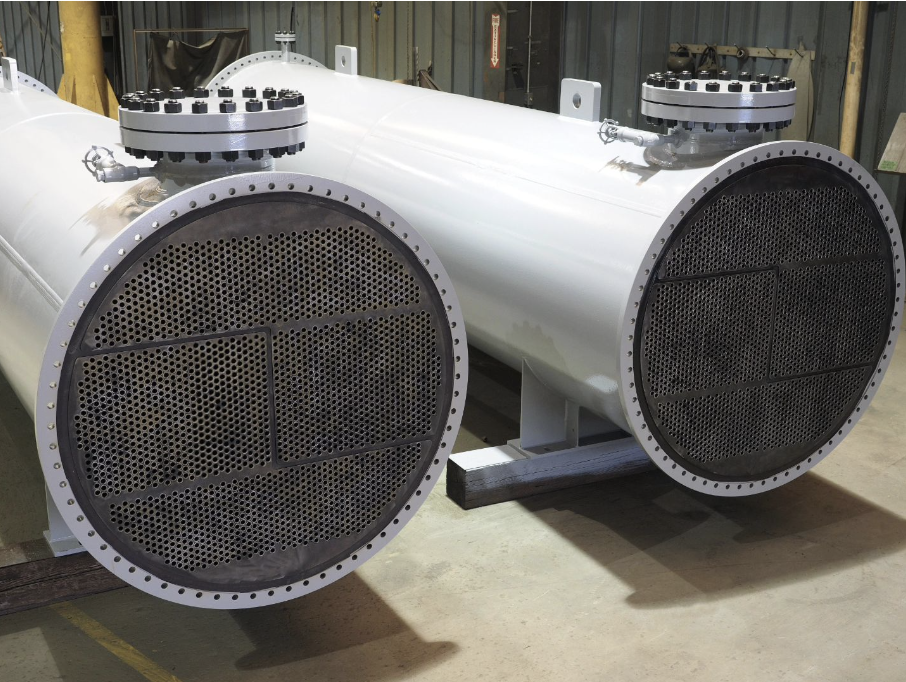

Custom Fabricated PROCESS

VESSELS & EQUIPMENT

Distillation Columns& Towers Fabrication

DISTILLATION COLUMNS & TOWERS

for Industrial Applications

WHERE ENGINEERING MEETS FABRICATION

IMPACT THROUGH SERVICE

Bendel’s seasoned teams have delivered service excellence and an unwavering commitment to quality and safety for over six decades.

We define our success by how we impact the lives of the people around us.

PROVEN PERFORMANCE BY DESIGN

FREE Download: Product Information Flip Book

Download Our Product Information Flip Book Now to Receive:

- Complete Overview of Bendel Products & Services

- Detailed Review of Capabilities & Materials Expertise

- List of Software Applications Utilized By Our Teams

- More...

Our Company

CAREERS

Join a team that is continually breaking new ground and pushing boundaries in engineering, fabrication, construction, site installation and field services delivering solutions to customers across all phases of the oil and gas value chain.

HSE

At Bendel you’ll be part of a family where you can contribute and make a difference—with the opportunity to advance your career in a fast-growing market where the sky’s the limit!

MISSION & VALUES

We offer competitive salaries and benefits to qualified applicants. View our current job openings now:

Charlotte, NC

Custom Industrial Fabrication

ASME, API, TEMA

McGregor, Texas

Custom Industrial Fabrication

ASME, API, TEMA

Beaumont, TX

Custom Industrial Fabrication

ASME, API, TEMA

Indianapolis, IN

Custom Industrial Fabrication

ASME, API, TEMA

Sisters, OR

Custom Industrial Fabrication

ASME, API, TEMA

Rocky Mount, NC

Custom Industrial Fabrication

ASME, National Board 'R'