Pharmaceutical Industry

Pharmaceutical-Grade Tanks, ASME Vessels, Equipment & Piping Fabrication Solutions

Pharmaceutical Industry

MARKETS - PHARMACEUTICAL INDUSTRY

Bendel is a proud partner to a wide variety of pharmaceutical owner operators and their engineering construction contractors, with over six decades of experience fabricating tanks and equipment for leaders in the industry.

In addition to delivering outstanding quality, shop-built and field-erected vessels and equipment, Bendel also offers an array of related services including logistics/permitting, installation, commissioning and startup; routine maintenance, R-stamp repair, parts refurbishing and upgrades.

PHARMACEUTICAL INDUSTRY TANKS & EQUIPMENT

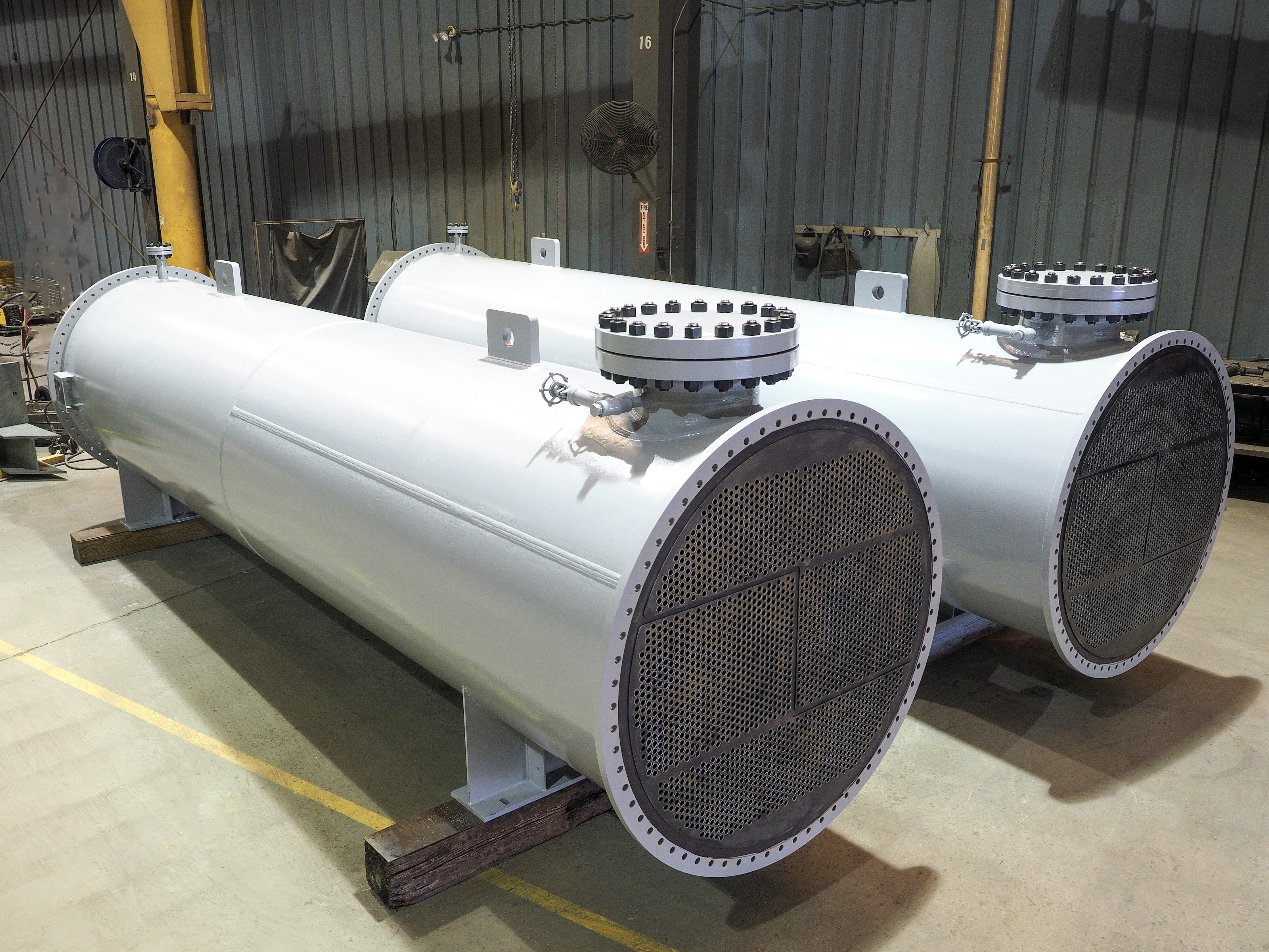

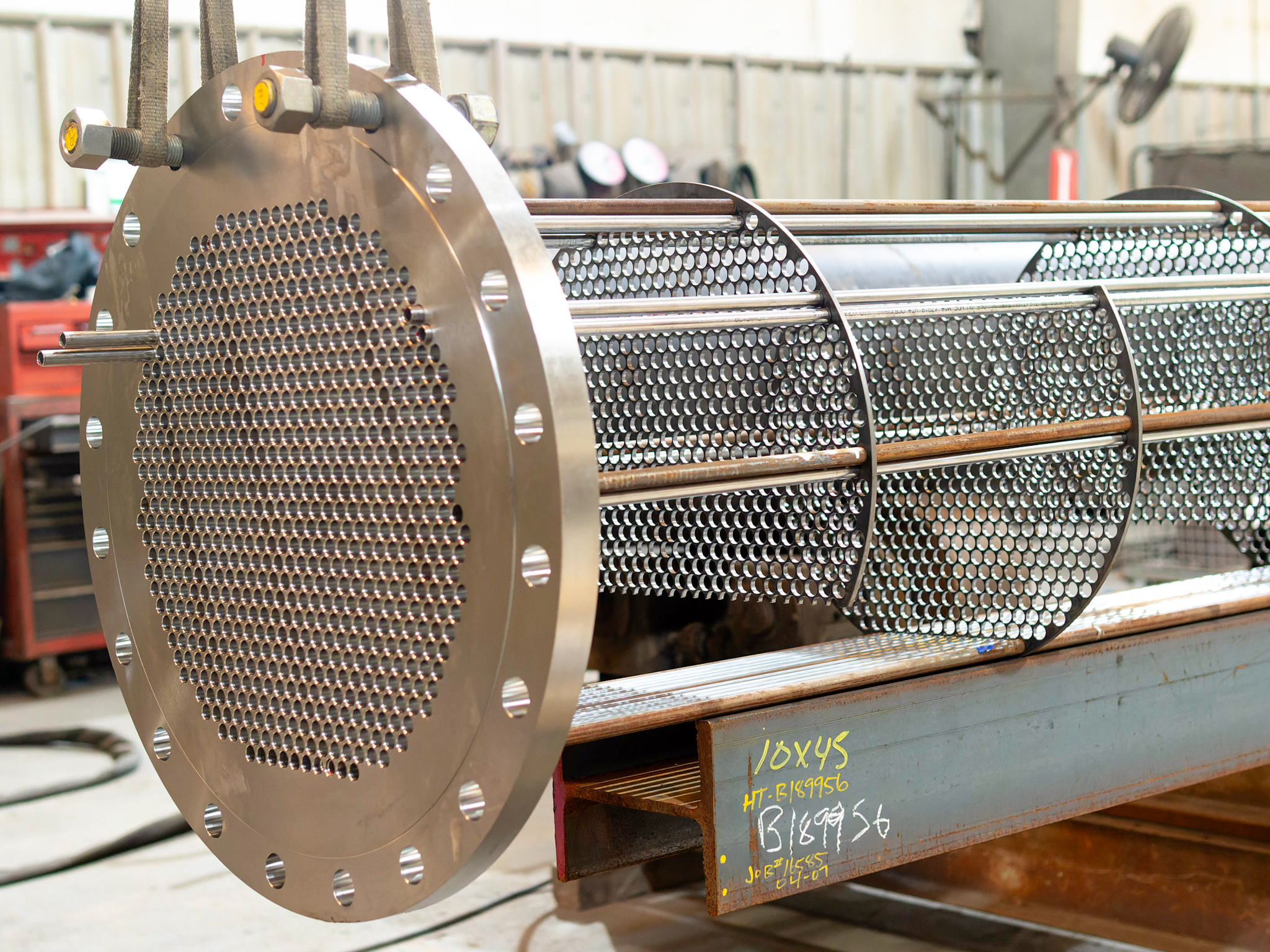

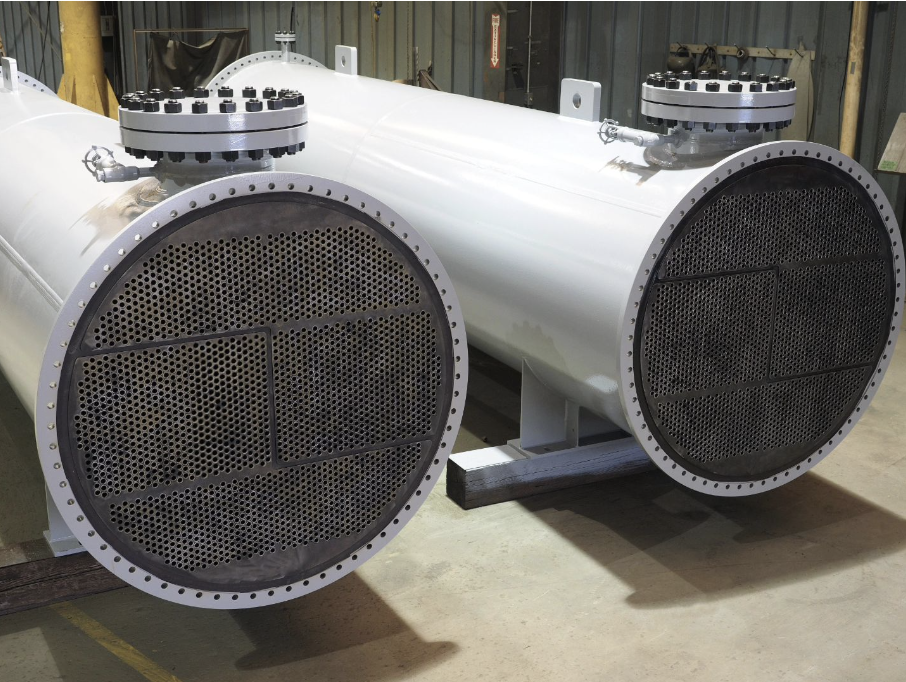

The Pharmaceutical industry makes use of pressure vessels, reactors, mixing tanks, melting tanks, heat exchangers and cooling towers to convert raw materials into finished products including drugs, medicines, and vaccines.

Distillation columns are also widely utilized for separation, solvent swapping, drying, and purification while traditional storage tanks are used for both the storage of flowable raw materials and finished pharmaceutical goods.

IMPECCABLE, HIGHEST QUALITY SOLUTIONS

We understand the unique challenges of the pharmaceutical industry such as the necessity to adhere to stringent FDA standards including regulatory requirements that ensure safe, hygienic tanks and equipment; as well as cleaning and maintenance codes that safeguard product integrity.

Bendel designs, fabricates and polishes an array of custom vessels to meet the demanding requirements of the pharmaceutical industry and satisfy specified purity requirements for the processing of both sterile and non-sterile liquids.

We specialize in the custom design and fabrication of corrosion-resistant pharmaceutical manufacturing equipment using specialty metals including High-Nickel Alloys (Hastelloy, Monel, Inconel), Duplex Stainless Steel and Austenitic 300 Series Stainless Steels, and Super Austenitic Stainless Steel Alloys that:

- Deliver excellent corrosion resistance

- Meet stringent sanitary requirements

- Optimize performance & reliability

- Prevent cross contamination

- Provide material traceability/documentation

- Improve yields

- Minimize process leaks

- Maximize safety

- Comply with ASME, API, TEMA, or UL codes

- Adhere to stringent QA/QC procedures

Bendel’s highly skilled personnel can also provide heating/cooling jackets with insulation and a sanitary protective skin.

We also routinely design and install clean-in-place (CIP) systems into final assemblies to allow for cleaning without disassembly.

Bendel has in-depth expertise in the design, fabrication, inspection and testing of pharmaceutical tanks and equipment including:

- ASME Rated Sanitary Pressure Vessels

- CIP Vessels

- Heat Exchangers

- Cooling Towers

- Melting Tanks

- Mix Tanks

- Reactors

- Sterile Holding Tanks

We're here to serve you and provide the highest quality custom-built pharmaceutical storage tanks and equipment to meet your unique application requirements. We welcome the opportunity to provide you a quote!

CONTACT US

Call us today at: 866-596-5112 to learn more about our custom engineering and fabrication services and discuss your needs - or request a quote below.

FREE: Project Sample

Receive a complete sample Bendel project proposal, including:

- Complete sample project budget

- Complimentary concept evaluation

- Lead time evaluation

- Cost analysis

- More...