Coating & Painting

Sand & Bead Blasting, Coating & Painting

Coating & Painting

VESSELS, TANKS & EQUIPMENT BLASTING & COATING

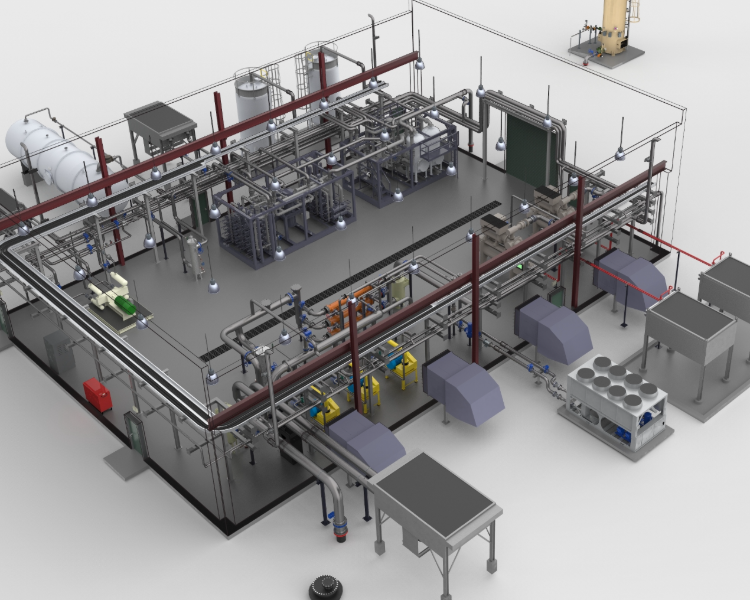

Bendel maintains state-of-the-art in-house blasting and coating operations to facilitate expert material surface preparation and the highest quality application of protective interior linings, exterior coatings and painting.

By utilizing our own in-house blast and coating operations rather than relying on third parties, we’re able to lower your project costs—and shorten project schedules—eliminating the added freight time and expense associated with moving product to-and-from third party locations prior to job site delivery.

SAND & BEAD BLASTING

Bendel's highly skilled technicians use the most advanced equipment and processes to blast material surfaces, effectively removing any mill scale, trace rust or other potential contaminants.

This process prepares vessel and equipment materials with the ideal surface profile for the outstanding coating adhesion and optimal bonding - for lasting performance.

Our unique, custom designed blast facilities allow our expert teams to rapidly and economically blast vessels in accordance with all related steel structures painting council (SSPC) profile and cleanliness standards.

Utilizing powerful equipment and processes, Bendel achieves blasting results to SSPC-SP-10 near white. Learn about our blasting, polishing, and passivation options here.

COATING & PAINTING

Bendel’s experienced coatings managers and technicians have the training and knowledge to work with virtually all industrial coatings including zincs, epoxies, and urethanes.

Our coatings help prevent corrosion caused by environmental exposure, fumes, humidity and immersion, and can be customized to meet your specific site characteristics and product storage requirements. Coating characteristics that offer high temperature and chemical resistance, waterproofing and UV resistance as well as other features can be specified to suit all your vessel and equipment finish needs.

STATE-OF-THE-ART FACILITIES

Our coating equipment consists of the latest technologies available and affords excellent quality and productivity.

In partnership with our parent company, TransTech, we deliver state-of-the-art painting and coating services from facilities in Texas and North Carolina, serving our East Coast and Gulf Coast customers as well as those across the U.S.

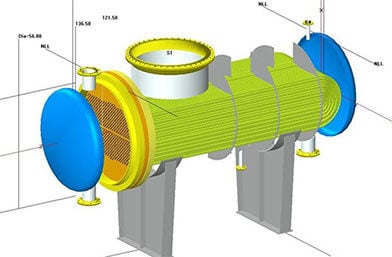

Offering extensive facilities, including two 525 linear feet parallel blast and paint runs, we have the ability to blast and paint tubular structures of 16’ diameter with lengths up to 200’.

CAPABILITIES

- On-site blasting & coating facilities for fast turn-around, lower cost

- Steel grit/sand abrasive blasting & cleaning

- Glass bead blasting & cleaning

- Pickling & passivation

- Polishing & buffing

- Horizontal and vertical shot blasting capabilities

- NACE/SSPC surface preparation standards

- Protective interior linings

- Protective exterior coatings & painting

- Zinc, epoxies, urethanes, enamel, vinyl ester

- NACE certified coating inspectors

PROTECTING YOUR HEALTH & THE ENVIRONMENT

The health and safety of our customers is of paramount importance to us. We use the safest, most eco-friendly materials available to protect you, your employees and the environment. Our non-silica based blasting materials are VOC-free and don’t leave harmful residues behind on your finished product.

Our experts can assist with coating selection and specification, environmental, and heath and safety concerns.

CONTACT US

Call us today at: (+1) 866.596.5112 to learn more about our coating & painting services and discuss your needs - or request a quote below.

FREE: Project Sample

Receive a complete sample Bendel project proposal, including:

- Complete sample project budget

- Complimentary concept evaluation

- Lead time evaluation

- Cost analysis

- More...

.jpg)

.jpg)