Fabrication Solutions

Fabrication Solutions

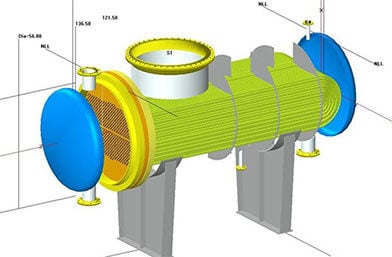

CUSTOM VESSEL & EQUIPMENT FABRICATION EXPERTS

Bendel’s state-of-the-art fabrication facility brings together cutting-edge equipment resources and highly-skilled, experienced engineering and fabrication teams, offering the highest quality fabrication, production, design and engineering solutions to clients in the chemical, petrochemical, pharmaceutical, paint & coatings, food & beverage, personal care, and water/wastewater management industries and others

Our modern fabrication facility encompasses more than 65,000 sq. ft. of manufacturing area on a 12-acre site located less than 1 mile from Interstate Hwy’s I-85 & I-77.

As a subsidiary of TransTech Energy, we leverage all company facilities and locations across the U.S. to execute and deliver projects cost-effectively, efficiently and to optimal schedules.

Learn more about our qualifications and services below!

CERTIFICATIONS

- ASME U, U2, U3, and S certifications

- NBIC certifications

- TEMA class R, C & B

- API-660, API-650, API-620

- NFPA-58, NFPA-22

CONTACT US

Contact us today at: 866-596-5112 to learn more about our fabrication services or request a quote:

Fabrication Facilities

McGregor, TX

- 170,000 sq. foot fabrication facility

- 100 acres of on-site storage

- Close vicinity to Interstate 35; BNSF and Union Pacific railroads; and the ports of Houston and Corpus Christi.

Charlotte, NC

- 65,00 square foot fabrication facility

- 12 acre site

- Convenient access major highways - less than 1 mile from Interstate Highways I-85 and I-77

Rocky Mount, NC

- 25,000 square foot fabrication facility

Qualifications & Services

MATERIALS

- Carbon Steel

- Austenitic Stainless Steel - 304, 310, 316L, 317L, 321, 347

- Super Austenitic Stainless Steel - ALLOY 20, 904L, AL6XN

- Duplex Stainless Steel - 2205, 2507

- HASTELLOY - C22, C276, C2000

- Other Nickel Alloys - Nickel 200/201, Monel 400

SOFTWARE

- COMPRESS: Mechanical Design of Pressure Vessels, Reactors, and Shell & Tube Heat Exchangers

- HTRI: Thermal analysis of Shell & Tube Heat Exchangers

- AME Tank – Rapid configuration, design, and detailing of above-ground storage tanks

- CUSTOM “In-House” programs: Developed by our experienced engineering sta for the efficient creation of Bill of Materials and Customer Quotations

- PVElite

- Aspen Shell and Tube (thermal and mechanical)

- Nozzle Pro for FEA

- Inventor

- AutoCAD Plant 3D

EQUIPMENT

- CNC Cutting tables - plasma & oxy

- (4) plate rolls - 6’, 10’, 12’ and 16’ - up to 3.25”

- TSAM – tubular seam alignment machine

- In-house Blast & Coating facility

- State-of-the-Art CNC high-speed milling and drilling machine designed to provide close tolerance machining

- Quickmill Intimidator 96: Superior solution for large part machining and drilling accuracy that provides a powerful, precise tool that performs flawlessly time after time. Bed size of 96” x 185-1/2”

- Overhead cranes - over 600,000 lbs lifting capacity

- MIG, TIG & SAW welding machines

- Angle rolls

- 1/2" x 12' 300 ton press brake

- 3/8" x 17' circle shear

- 16' long cold wire TIG seam welder

SERVICES

- Design & Engineering

- ASME Fabrication

- On-site NDE (RT & PAUT)

- Vessel & Equipment Storage & Staging

- Logistics/Permitting, Heavy Hauling & Delivery

- Tank Set & Installation

- Commissioning & Startup

- Contract In-House Machining, Milling and Tubesheet Drilling Capabilities

- R-Stamp Repair & Modification – Shop & Field

- In-field Maintenance & Upgrades

- In-field Consultative Trouble-Shooting

- Training Quality Control

IN-HOUSE QUALITY ASSURANCE PROGRAM

- QA team includes experienced staff representing on average over 25 years of experience.

- Authorized third-party Level III and Level II inspectors

- CWI and AWS Certifications

- Positive material identification (PMI)

- Helium leak detection

- Phased array ultrasonic testing

- Radiography

- LP (dye penetrant) & MT (mag particle) testing

- Comprehensive internal and supplier tracking

- Our team members have obtained highly beneficial quality training and certifications including:

- ASME Section V/Section VIII Div. 1:

- ASNT-SNT- TC-1A, UT Level II

- ASNT-SNT-TC-1A, MT Level II

- ASNT-SNT-TC-1A, PT Level II AWS:

- QC1, CWI

- ASNT-SNT-TC-1A, UT Level I

FREE: Project Sample

Receive a complete sample Bendel project proposal, including:

- Complete sample project budget

- Complimentary concept evaluation

- Lead time evaluation

- Cost analysis

- More...

.webp)

.webp)

.webp)

.jpg)

.png)

.jpg)

.jpg)

.jpg)

.webp)

.webp)

.webp)