Contract Machining & Drilling

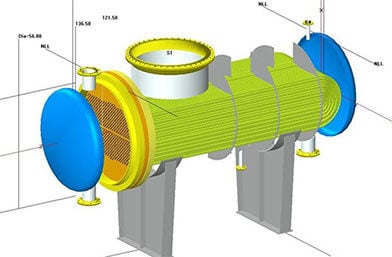

Turnkey fabrication of Shell and Tube Heat Exchanger Components

Contract Machining & Drilling

CONTRACT INDUSTRIAL CNC MACHINING & DRILLING SPECIALISTS

In addition to delivery of complete shell and tube sheet heat exchangers, Bendel offers contract CNC machining and drilling services, allowing clients to benefit from our superior tools and quality—no matter what their need.

HEAT EXCHANGER SPECIALISTS

With our state-of-the-art CNC drilling center and in-house vertical turning lathe, our production facilities support turnkey fabrication of all shell and tube heat exchanger components, offering superior flexibility to both OEMs and their supply chain partners.

Example Projects:

- Tube sheets

- Clad tube sheets

- Baffles

- Flanges

- Partition Plates

- Support plates

- Connections/ Inlets/Outlets

- Installation Mountings, Saddles

- End Caps

- Channel Covers

- Vents

- Valves

- Lift Lugs

- Tube Bundles - Plain, Longitudinally Finned, and Studded

OUTSTANDING QUALITY

With the highest quality in-house precision-machining, welding and assembly capabilities, we deliver custom and turnkey fabricated heat exchanger components for the most demanding applications and environments—consistently achieving industry-leading performance and reliability.

Learn more about our specialized equipment below!

TOTAL APPROACH TO FLEXIBILITY

Bendel offers total project flexibility—including the convenience of optionally shipping your own materials to us OR choosing for us to purchase materials on your behalf and shipping finished products directly to your door!

MATERIALS

- Carbon Steel

- Stainless Steel

- Nickel Alloy

- Duplex

CAPABILITIES

- ASME BPVC – Section VIII, Div 1

- TEMA C for general applications

- TEMA B for chemical manufacturing

- TEMA R and API-660 for refining operations

- ASME BPE (bioprocessing equipment) for pharmaceutical applications

- ASME 3A for sanitary dairy, food and personal care applications

- FDA

CONTACT US

Bendel has earned a reputation for providing special attention to our customers’ unique requirements. Our fabrication specialists work with you to create optimal solutions that are designed and fabricated specifically to suit your applications. We welcome the opportunity to provide you with a quote!

Call us today at: 866-596-5112 to learn more - or request a quote below.

FREE: Project Sample

Receive a complete sample Bendel project proposal, including:

- Complete sample project budget

- Complimentary concept evaluation

- Lead time evaluation

- Cost analysis

- More...

EQUIPMENT

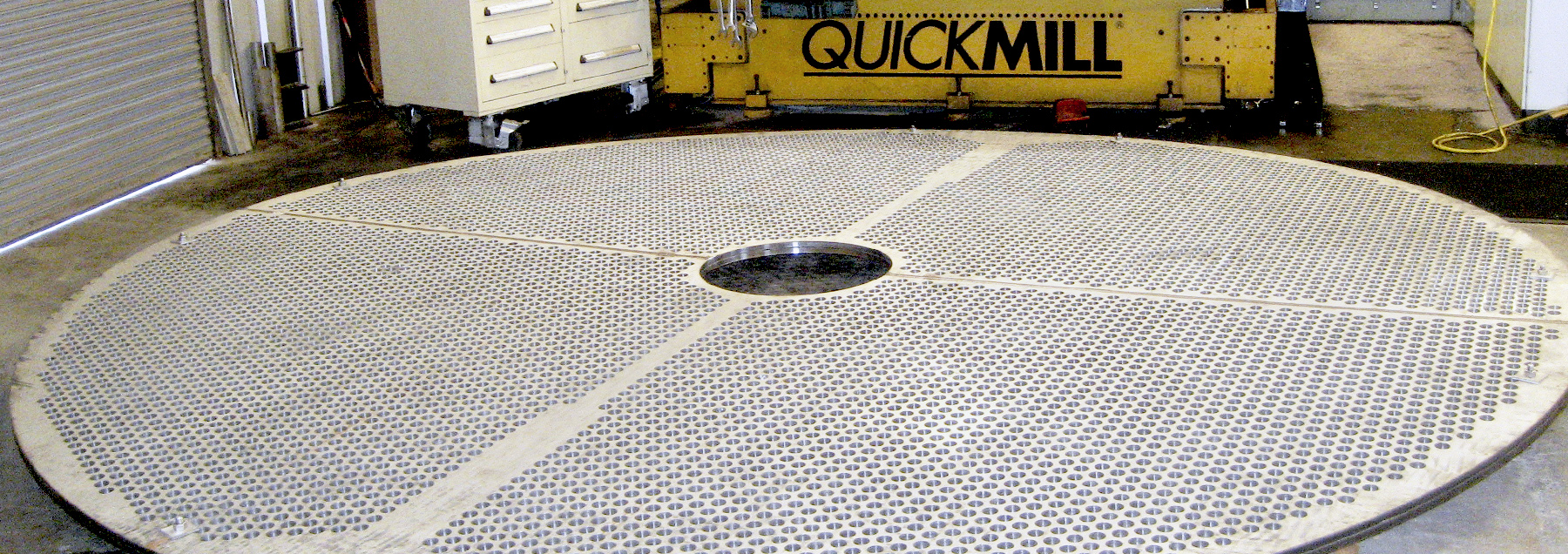

QUICKMILL MACHINING & DRILLING

Our Quickmill Intimidator Gantry 96 (96″ x 185.5″) is a superior solution for large part CNC machining and drilling accuracy and is widely accepted as the industry benchmark for delivering drilling performance.

The Quickmill provides our craftsmen with a powerful, precise tool that performs flawlessly time after time, while supporting increased production efficiency and industry-leading quality and performance. Learn more.

Headline

Add your content here.

%20Boring%20Mill.jpg)

KING VERTICAL TURRET LATHE (VTL) BORING MILL

- 100" Table Dia.

- Dual Ram

- Elevating cross rail with a maximum working height of 72"

- New Technology Variable Speed Drive

Model 100

Headline

Add your content here.

ARC CUT PRO 20 PLASMA TABLE

- Hypertherm XPR300 Plasma cutting system

- 8 FT. x 20 FT. working table

- Cut up to 3" Thick Stainless Steel

- Atek Controller

Headline

Add your content here.

JETLINE LONGITUDINAL SEAM WELDER/SEAMER

- Up to 3/8" Thick plate seaming capability

- Seam up to 194" Length material

- New Jetline 9900 System Controller

- Two Miller Maxstar 800 TIG Weld Power Supplies

Headline

Add your content here.

.webp)

.webp)

.webp)

.jpg)

.png)

.jpg)

.jpg)

.jpg)

.webp)

.webp)

.webp)