Textiles Industry

TEXTILES INDUSTRY

MARKETS - TEXTILES INDUSTRY

Bendel has a long history serving textile manufacturers. In fact textile companies represented the largest users of Bendel’s fabricated products prior to movement of the industry off-shore.

Today, Bendel continues to serve a broad array of U.S.-based textile mills, with over six decades of experience fabricating specialty tanks and equipment for leaders in the industry.

In addition to delivering exceptional quality, shop-built vessels and equipment, Bendel also offers an array of related services including logistics/permitting; tanks and equipment installation; commissioning and startup; routine in-field maintenance; R-stamp repair, parts refurbishing and upgrades.

TEXTILE INDUSTRY TANKS & EQUIPMENT

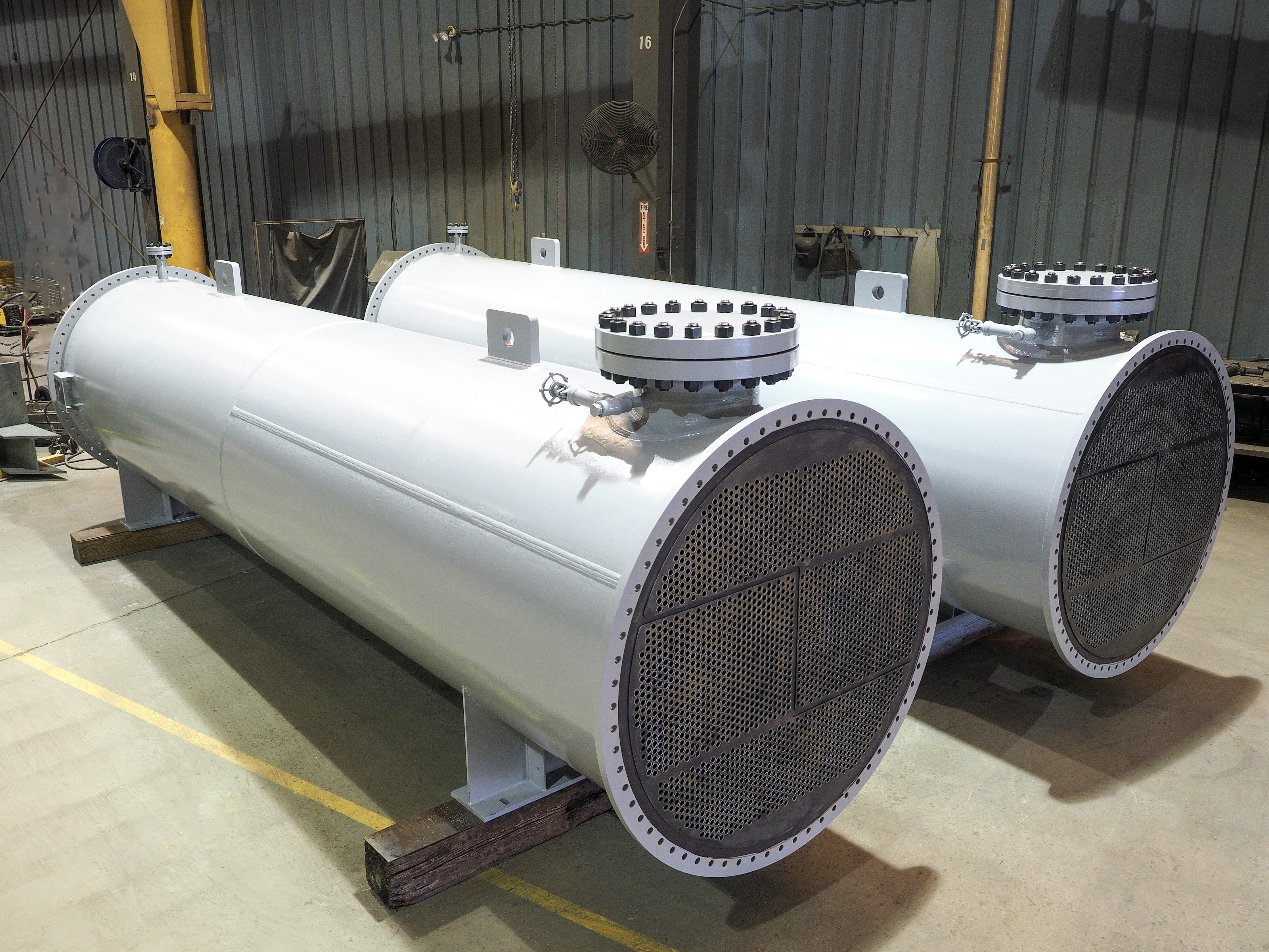

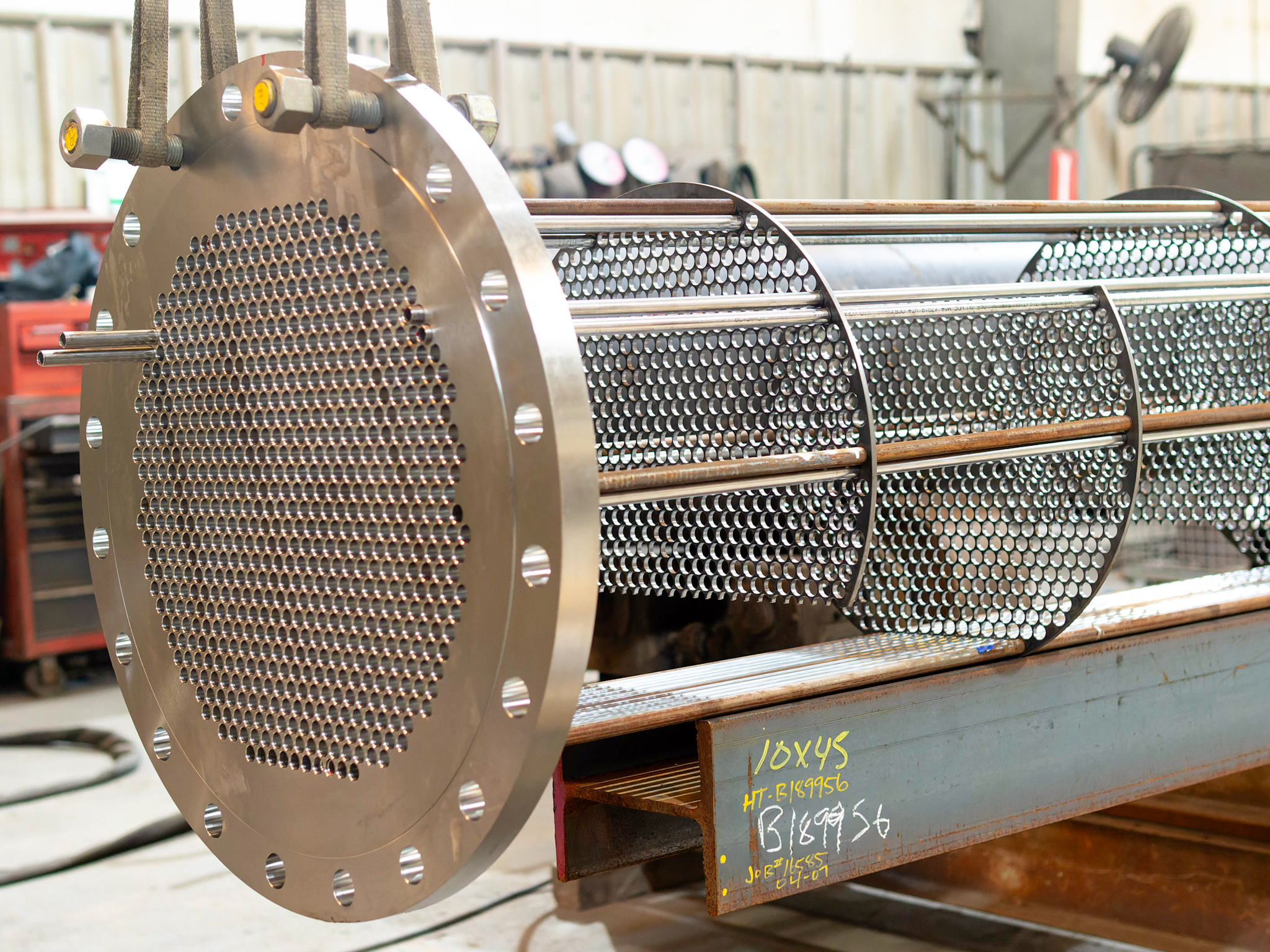

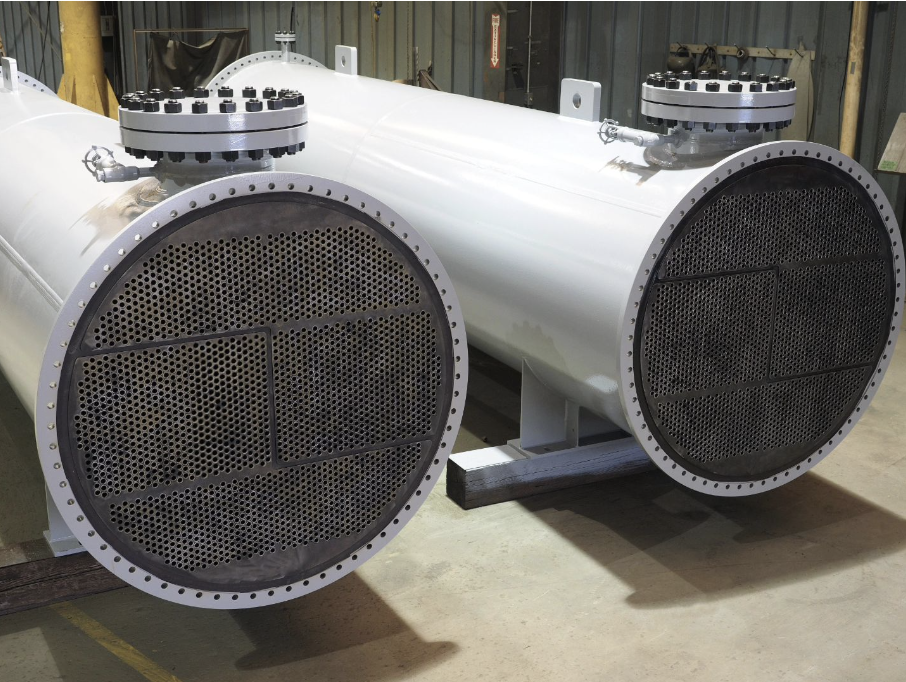

The Textile Industry makes use of dye becks, mixing tanks, reactors, shell and tube heat exchangers and other specialized fabricated equipment for the dyeing, treatment, and conditioning of yarns and fabrics.

Storage tanks are also used throughout textile manufacturing processes for the storage of dyes and other liquids as well as the interim storage of produced wastewater.

DELIVERING QUALITY, RELIABILITY

We understand the unique challenges of textile mill operations, including the need for high-quality, custom-fabricated vessels and equipment for highly specialized applications.

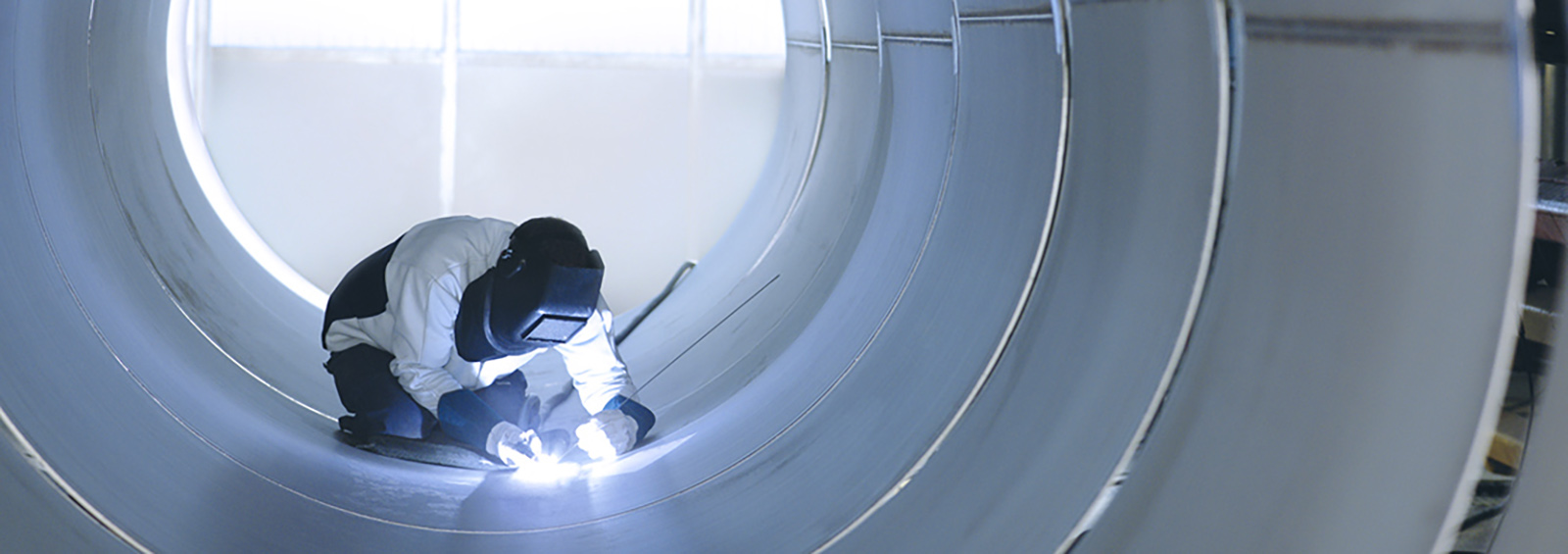

Offering custom industrial equipment engineering and fabrication expertise, unmatched metalworking skills, heavy steel fabrication capabilities and highly skilled ASME code pressure vessel design, engineering and fabrication, we deliver the highest-quality, long-lasting vessels and equipment to our textile industry customers.

STATE-OF-THE-ART FABRICATION FACILITIES

Utilizing the most cutting-edge equipment at our state-of-the-art fabrication facilities, we specialize in the custom design and fabrication of corrosion-resistant tanks and equipment using

specialty metals including High-Nickel Alloys (Hastelloy, Monel, Inconel), Duplex Stainless Steel, Austenitic 300 Series Stainless Steels, and Super Austenitic Stainless Steel Alloys that:

- Deliver excellent corrosion resistance

- Optimize performance & reliability

- Prevent cross contamination

- Improve yields

- Minimize process leaks

- Maximize safety

- Comply with ASME, API, TEMA, or UL codes

-

Adhere to stringent QA/QC procedures

Bendel delivers the highest quality custom fabricated tanks and equipment to serve the diverse needs of textile manufacturers. Our seasoned teams have in-depth expertise in the design, fabrication, inspection and testing of process vessels and equipment including:

- Pressure Vessels

- Reactors

- Mixing Tanks

- Dye Becks

- Shell & Tube Heat Exchangers

- API-650 and API-620 Storage Tanks

Our engineers and fabricators can work from your own drawings or CAD designs or those provided by engineering companies and consultants working in the textiles sector. Or let us design and engineer your equipment for you to meet your specific needs.

We're here serve you and we welcome the opportunity to provide you a quote!

CONTACT US

Call us today at: 866-596-5112 to learn more about our custom engineering and fabrication services and discuss your needs - or request a quote below.

FREE: Project Sample

Receive a complete sample Bendel project proposal, including:

- Complete sample project budget

- Complimentary concept evaluation

- Lead time evaluation

- Cost analysis

- More...