CUSTOM Heat Exchanger Fabrication

CUSTOM FABRICATED HEAT EXCHANGERS - TO YOUR SPECIFICATIONS

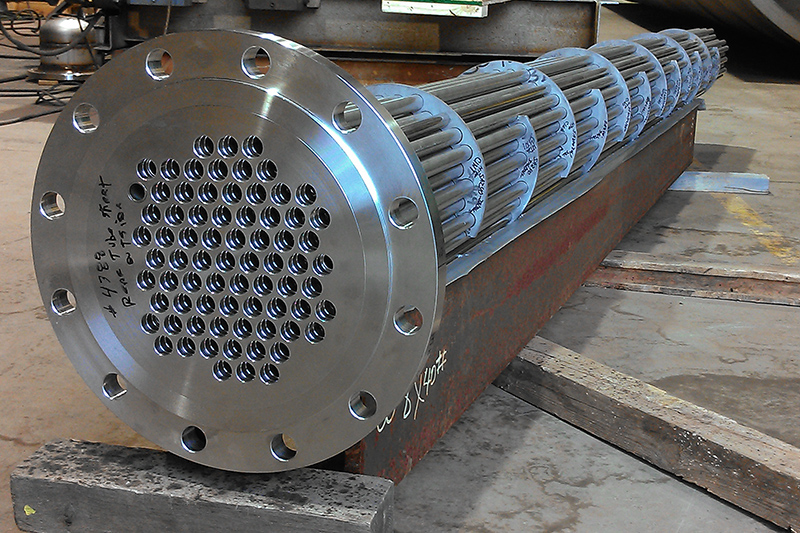

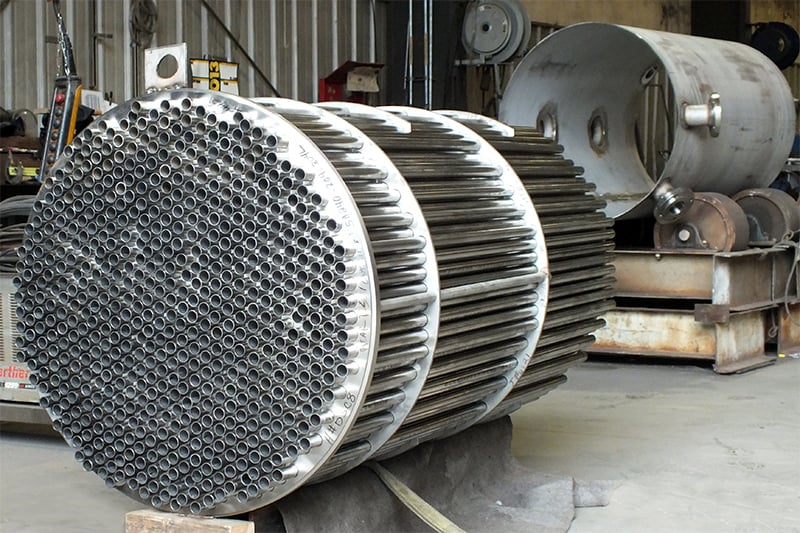

Bendel specializes in the custom design and fabrication of Shell & Tube Heat Exchangers for the chemical industry.

We have the capabilities and expertise to size, design and fabricate your heat exchanger to your exact specifications and to the highest standards.

Utilizing advanced HTRI thermal design and Compress software and backed by decades of experience and design expertise, our seasoned team of mechanical and thermal design engineers will work with you to determine the optimal custom solution to meet your specific process requirements.

SAFE, RELIABLE SOLUTIONS

We understand how important reliability is to maintaining your operations and the need for safe, effective solutions that allow for easy inspection, cleaning and maintenance to ensure safe, reliable operations—and long equipment life.

That’s why all our heat exchangers are designed, inspected and rigorously tested at our facilities to meet stringent pressure, temperature and mechanical design standards including:

- ASME BPVC – Section VIII, Div 1

- TEMA C for general applications

- TEMA B for chemical manufacturing

- TEMA R and API-660 for refining operations

- ASME BPE (bioprocessing equipment) for pharmaceutical applications

- ASME 3A for sanitary dairy, food and personal care applications

- FDA

PURPOSE-BUILT

Our experienced engineering and fabrication teams have the knowledge and experience to deliver a broad range of world-class solutions to serve the specific needs of a broad range of industries.

Just a few of the custom heat exchangers we design and build include:

|

|

CAPABILITIES

Our Shell & Tube Heat Exchangers can be fabricated from Carbon Steel, Stainless Steel, Nickel Alloy and Duplex

We manufacture a variety of heat exchanger types with options and characteristics to suit virtually any purpose including:

|

|

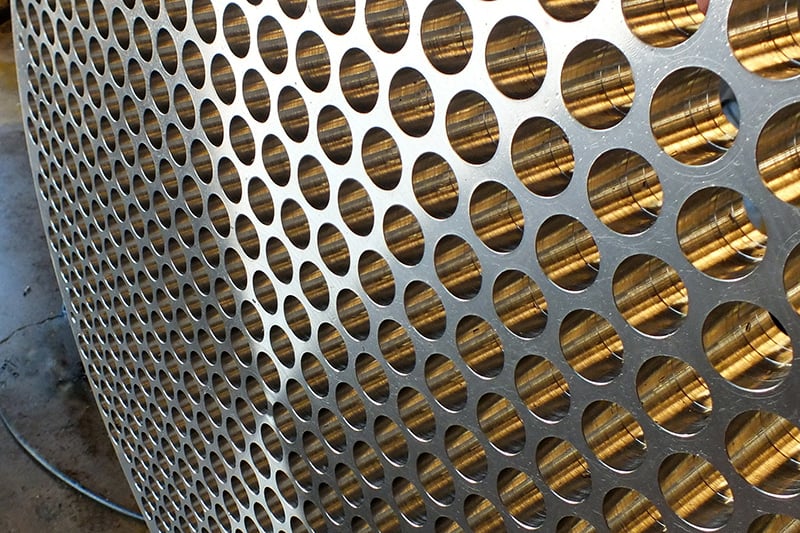

When they entrust a heat exchanger project to us, our clients demand perfection—and we rely on our state-of-the-art Quickmill milling and drilling machine to deliver. Designed to provide outstanding, close tolerance machining of tubesheets used in the manufacture of our custom Shell & Tubesheet Heat Exchangers, our Quickmill Intimidator improves the quality and performance of every heat exchanger we build.

- Quickmill Intimidator 96: Superior solution for large part machining and drilling accuracy that provides a powerful, precise tool that performs flawlessly time after time. Bed size of 96” x 185-1/2”

EXPANSION TANKS

Bendel also offers a full array of custom ASME stainless steel expansion tanks to accommodate expanding fluids and reduce pressure in closed loop heating systems.

CONTACT US

Bendel is here to serve you and provide the highest quality custom built Shell & Tube Heat Exchangers to meet your application's requirements. We welcome the opportunity to provide you a quote.

Call us today at: 866-596-5112 to learn more about our custom engineering and fabrication services and talk about your upcoming distillation columns or towers project - or request a quote below.

Metallurgy

FREE: Preliminary Project Development Package

Receive a complete Bendel project proposal, including:

- Complete sample project budget

- Complimentary concept evaluation

- Lead time evaluation

- Cost analysis

- More...

PARTIAL LIST OF HEAT EXCHANGER TYPES/CAPABILITIES

- Fixed Tubesheet Heat Exchanger

- U Tube Heat Exchanger

- Removable Tube Heat Exchanger

- Floating Head Heat Exchanger

- Kettle Reboiler Heat Exchanger

- BEM type Heat Exchanger

- AEL type Heat Exchanger

- AEM type Heat Exchanger

- NEN type Heat Exchanger

- BXM type Heat Exchanger

- AFM type Heat Exchanger

- BFM type Heat Exchanger

- BEU type Heat Exchanger

- BKU type Heat Exchanger

- AES type Heat Exchanger

- AEP type Heat Exchanger

- AET type Heat Exchanger

- AEW type Heat Exchanger

- AKT type Heat Exchanger

- CFU type Heat Exchanger

- Shell & Tube Heat Ecxhanger

- Oil to Oil Economizer

- Steam Trim Heater

- Trim Cooler

- Condenser

- Evaporator

- Reboiler

Project Gallery