Pastilles Dissolution Heat Exchangers

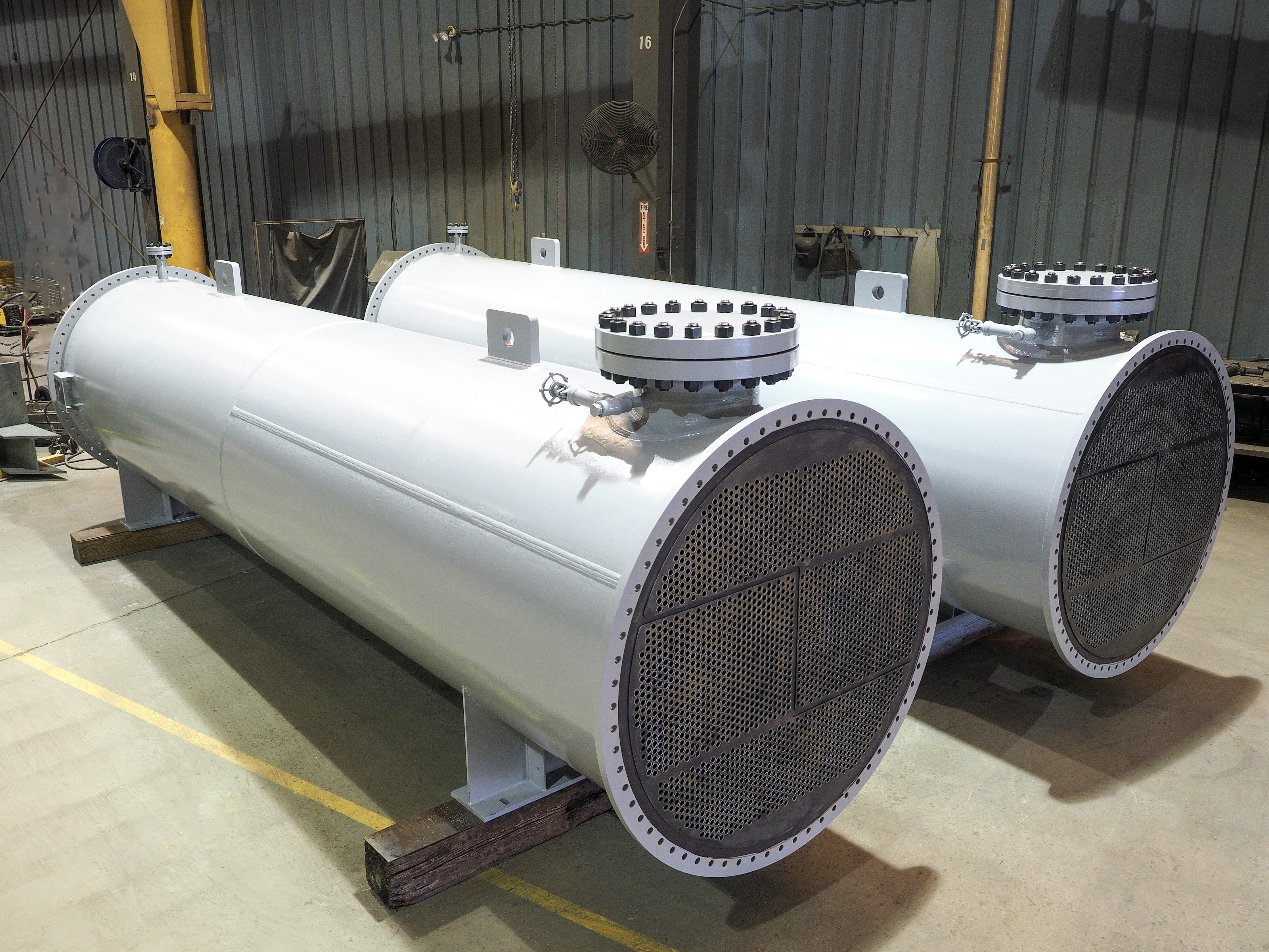

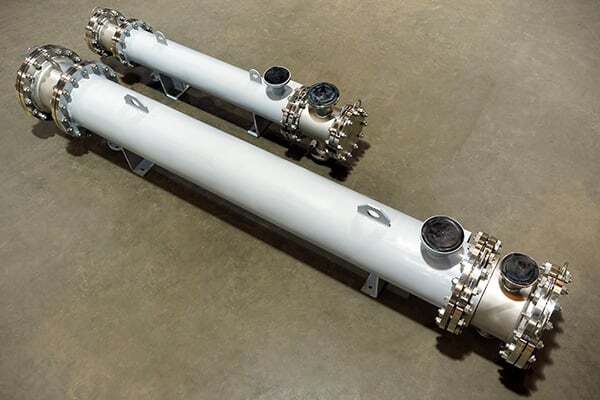

Pastilles Dissolution Heat Exchangers These heat exchangers are part of a replacement project for a nitrogen fertilizer plant in Georgia. 15.25”...

|

Enhancing Chemical Industry Efficiency

For more information download our FREE Case Study below:

|

Pastilles Dissolution Heat Exchangers These heat exchangers are part of a replacement project for a nitrogen fertilizer plant in Georgia. 15.25”...

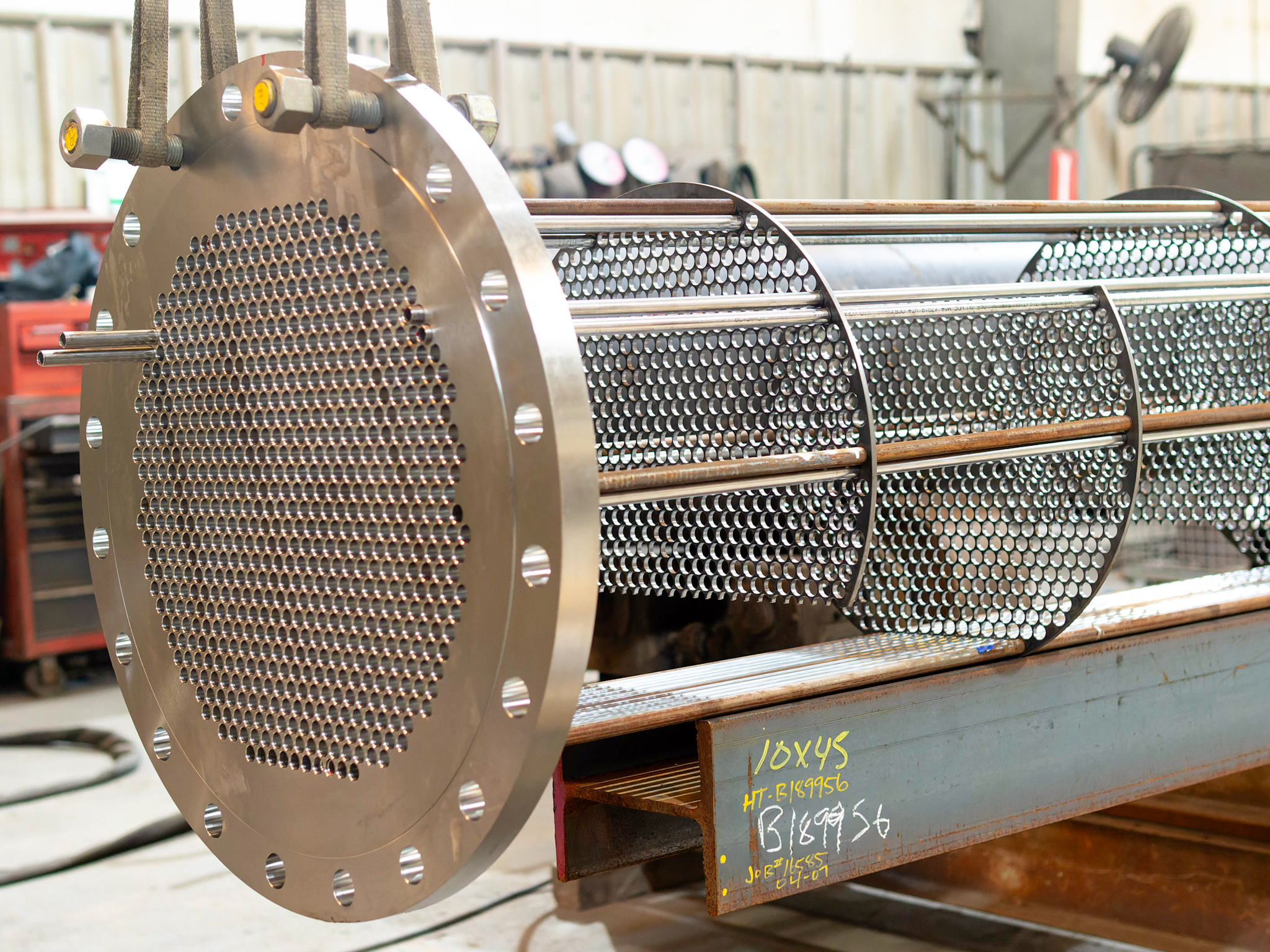

Improving Chemical Industry Efficiency Vertical BEM heat exchanger ASME and TEMA compliant design Carbon steel shell, stainless tubes Built...

ASME Vertical Heat Exchanger for Petrochem We recently delivered an ASME Vertical Heat Exchanger to a Petrochemical Customer in Southeast...