Columns - Metal Anodes Processing Plant

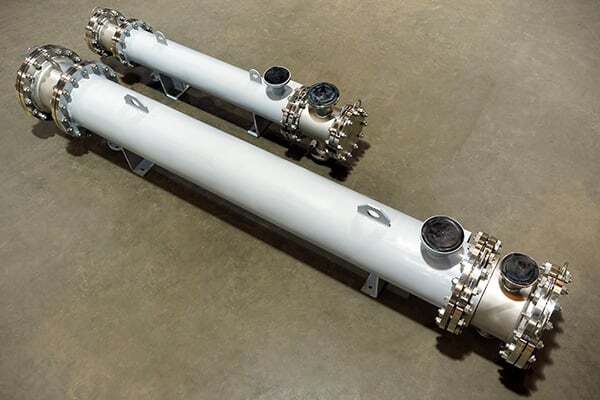

Nitrate Column Reactors Fabrication Bendel recently delivered a (15) vessel project for a metal anodes processing plant in Tennessee, including:

Replacement Pressure Vessel

| We recently delivered a replacement pressure vessel for a chemical process facility in the southeast US: Blowdown collection tank:

Blowdown Tanks are a key component of a steam heating system. Small quantities of particles are gathered in the boiler when evaporation of steam dissolves contaminants from the water and pipework in these systems as water changes to steam. |

Nitrate Column Reactors Fabrication Bendel recently delivered a (15) vessel project for a metal anodes processing plant in Tennessee, including:

Pastilles Dissolution Heat Exchangers These heat exchangers are part of a replacement project for a nitrogen fertilizer plant in Georgia. 15.25”...

Advancing Chemical Industry Efficiency Custom fabrication of 6,000-Gallon Hastelloy C-276 Reactor Zone shell and bottom half pipe jacket...