Mixing & Finishing Tanks Fabrication

Mix Tanks Fabrication & Installation (18) 5,000-gallon mixing & finishing tanks and equipment delivered to a midwest regenerative agriculture...

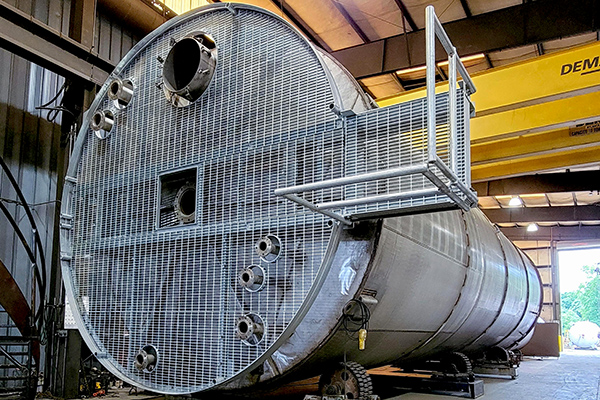

Bendel is proud to support the rapid expansion of the semiconductor and electronics industry with high-quality, custom-engineered process equipment. Our latest project—a 10,500-gallon vertical water shower tank fabricated for a new semiconductor manufacturing facility in Texas—demonstrates the level of precision, reliability, and craftsmanship required for mission-critical industrial applications.

This tank will support advanced manufacturing processes for AI chips, high-performance computing (HPC), and 5G technologies, contributing to a larger industry effort to strengthen U.S. semiconductor production capacity and stabilize global supply chains.

Capacity: 10,500 gallons

Dimensions: 168” diameter × 115” straight side

Design Code: API-650

Material: 304/304L stainless steel (mill finish)

Head Design: Conical top head with flat flanged bottom head

Structural Enhancements: Top head stiffeners and anchor lug supports

Access & Connectivity: Two manways and 23 nozzle connections

Safety & Compliance: Stainless steel OSHA handrail, safety gate, and caged ladder

This configuration provides durability, corrosion resistance, and precise integration capability—essential for semiconductor water processing systems where cleanliness, reliability, and uptime are non-negotiable.

Explore more about how Bendel supports semiconductor and advanced electronics manufacturers with custom tanks, pressure vessels, and heat transfer equipment engineered for high-purity, high-reliability environments: Learn More

|

Mix Tanks Fabrication & Installation (18) 5,000-gallon mixing & finishing tanks and equipment delivered to a midwest regenerative agriculture...

Soybean Processing Facility Project Bioindustrial Alternatives Mix Tank for a soybean processing facility project in the Midwest: 58,000 Gallon...

1st Effect Evaporator Project This project was delivered to a Lithium Hydroxide Monohydrate processing plant for a North Carolina client. 44"...